Indian handloom industry still disorganised: Designers

By Nivedita,

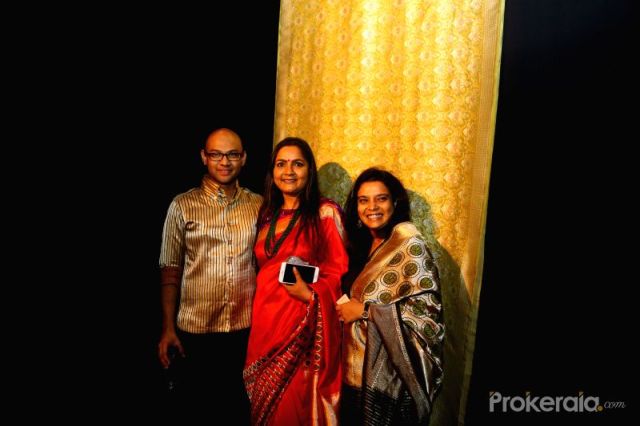

New Delhi : Designer duo Swati and Sunaina, who came together in 2007 with the aim of rediscovering the lost treasures of Indian woven textiles and offering them to a discerning audience, say the country’s handloom industry is still a very disorganised sector despite being so huge.

And as it is disorganised, the precision required to meet quality standards and the demands of the global market is missing. Such precision is possible “only if the sector is organised from start to finish, and standardised norms set by the government are stringently incorporated”, Swati told IANS in an email interview from Kolkata.

“Designers can and are already creating great silhouettes from Indian handlooms,” said Sunaina, adding that what is now required is a “lateral shift towards handlooms and appreciation of its quality and worth among those choosing to be dressed in Western cuts and patterns”.

“Alternatively, a sari, which is the most versatile unstitched garment draped and presented in many forms to create any desired silhouette, is suitable for the red carpet.”

The designer duo have infused innovation and freshness into their handloom work, which reflect in the motifs, colours and placements, culminating in limited-edition textiles that celebrate tradition.

All the handloom saris at their Kolkata store “Swati and Sunaina” are made on the pit looms of Banaras using techniques passed down the generations by master craftsmen. The use of pure, certified gold zari to intricately weave saris has been the hallmark of the label that consciously chooses quality over quantity.

For a few years now, they have worked with master weavers and this has involved understanding how such zari is made.

“The Banaras handloom industry is very versatile and adaptable” and open to influence and inputs, making it “easy for anyone to put their designs into the process of production. The weavers are known to pick any specialised form of weaving from any sector and re-create it — a case in point being Jaamdani of Bengal — making Banaras handloom a viable ‘Make in India’ product,” said Swati.

As designers, they like to retain the classicism of traditional Banarasi patterns and infuse freshness with play of modern colours and pattern placement, said Sunaina.

“An innovation in design and experiment that we successfully conducted was interpreting antique jewellery into woven design patterns and successfully creating a three-dimensional effect by playing with colours and intelligent weaving,” she said.

They feel fashion lovers today are great seekers of knowledge and love to arm themselves with finer details about the handlom that they choose to wear.

“Interestingly, I have observed that the newer generation is a quick learner of intricacies involved in the production of any handloom,” said Swati.

Added Sunaina: “Our challenges are more about creating awareness of the intricacies of procuring complexed textiles. As a solution to this, we have taken up educating young minds with informative videos about the processes involved in creating pure zari and textiles.”

They recently held an exhibition on art of zari titled ‘Gold’, which was curated by Mayank Mansingh Kaul. It showcased the process of the making of zari via a multi-media presentation, using photographs, film and video projections.

So how has zari work evolved from the past to the present?

“Zari has been an integral part of Indian handlooms (and) was always associated with wedding finery and richness. From the early 20th century, zari has undergone a revolution from being totally hand-drawn to being partially mechanised and this has made zari production easier and more (in volume),” Swati told IANS.

“Zari is created from precious metals, (so) textiles woven with real zari have a higher value,” said Sunaina, adding that they could only be afforded by a few. “It was always associated with royalty, nobility and wedding trousseau.”

“With time, the class barriers have disappeared and anybody with a desire and ability to buy has access to the finest.”

(Nivedita can be contacted at nivedita.s@ians.in)

—IANS